Anyone can execute an order when everything goes perfectly. The true measure of a wholesale partner isn’t found in the smooth initial quote or the prompt sample approval. It’s revealed in the critical moment when a problem arises—especially one that isn’t your fault. It’s about how you respond when your client says, “We need to change this, and we’re already on deadline.”

This is the story of how our team navigated exactly that scenario with a distributor in New York, reinforcing that the most valuable thing we supply isn’t just scarves—it’s trust and operational agility.

The Project: A Prestige Order for New York University

On December 10th, we were contacted by an established retailer based in New York City. Their request was specific and sizable: 5,000 pieces of satin polyester scarves, featuring a detailed, double-sided digital print of a custom New York University-themed pattern.

The process began efficiently:

- Streamlined Quoting: We provided a comprehensive, all-inclusive quote within hours.

- Swift Commitment: Satisfied with the transparency and value, the client proceeded with full payment—a sign of mutual trust from the outset.

- Pre-Production Sample: Upon receiving their final artwork, we immediately ran a pre-production sample (Prenatal sample). This critical step physically validates design, color, and hand-feel before mass production begins. The client approved it promptly.

Everything was on track. The designs were locked, production commenced, and the first 100 meters of fabric were successfully printed.

The “Crisis”: A Last-Minute Color Realization

Then, the email arrived.

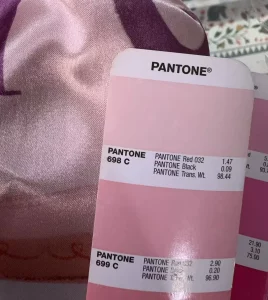

The client had reviewed the physical sample in different lighting and made a crucial observation: the purple hue had a subtle blue undertone, and the pink wasn’t quite the vibrant shade they envisioned for their collegiate audience. They provided precise Pantone Color references: 5135C for Purple and 698C for Pink.

This is a supplier’s crossroads. 100 meters of fabric—representing significant time and material—was already produced. The easy response could have been: “We’re sorry, but production has started. Changes now incur heavy fees and delays.”

But that’s not partnership. That’s transaction.

Our Response: The Anatomy of a Solution

Our team’s reaction was immediate and solution-oriented:

- Pause & Assess (Within 1 Hour): We halted the printing machine. The first priority was to prevent further “incorrect” production.

- Technical Feasibility Check: Our printing technicians analyzed the new Pantone values against our satin fabric base. Could we achieve a perfect match? The answer was yes. We confirmed the new inks could be calibrated without compromising the print’s clarity or hand-feel.

- Proactive Communication & New Proposal: We didn’t just say “yes.” We presented a clear, revised action plan to the client:

- Acknowledgment of the change request.Confirmation of technical change the printing color.

- A detailed timeline for producing a new fabric strike-off (a small swatch of fabric printed with the corrected colors).

- A transparent update on the revised production schedule.

Re-Creation & Re-Confirmation: We produced the new strike-off with the exact Pantone 5135C and 698C and expedited it to New York. This step is non-negotiable—absolute color confirmation before restarting bulk production.

The Outcome: Building More Than Scarves—Building Confidence

The client’s response was profoundly telling:

“We apologize for the late change and truly appreciate your incredible flexibility and cooperation. Your team’s responsiveness is exactly what we need in a partner.”

The new colors were approved. Production resumed with full alignment. What could have been a contentious, loss-incurring problem became a powerful testament to our collaborative model.

The Lesson for Your Business: Why Your Supplier’s Crisis Protocol Matters

This story isn’t about us being accommodating. It’s a case study in risk mitigation for your brand. When you choose a wholesale partner, you are entrusting them with your timeline, your budget, and your reputation.

Here’s what we demonstrated, and what you should demand from your supplier:

- Proactive Problem-Solving: We acted as an extension of our client’s team, focusing on “how to fix” not “who’s to blame.”

- Technical Expertise & Investment: We ability to make precise adjustments are what made a last-minute change possible without catastrophic cost.

- Process Integrity: Our built-in steps—like the pre-production sample and the strike-off stage—exist to catch these issues early, but our flexibility allows us to correct them late if needed.

- Communication as a Core Service: We kept the client informed at every single step, eliminating anxiety and building trust.

Ready for a Partnership That Handles the “What Ifs”?

Your next custom scarf, wrap, or shawl project deserves a partner whose default setting is “Yes, we can find a way.”Welcome to bizimle iletişime geçin.

To ensure we can collaborate with maximum efficiency from the very first inquiry, please provide:

- Your design/artwork (AI, PDF, or high-res PSD preferred).

- Desired dimensions (e.g., 70″x70″, 55″x55″).

- Target material (Satin Polyester, Mulberry Silk, Viscose Blend, Acrylic, Wool).

- Preferred printing/branding technique (Digital Print, Silk Screen, Jacquard Weave, Embroidery).

Click here to share your project details and receive a strategic quote within 24 hours.

Let’s build a collection—and a partnership—that’s prepared for success, and adaptable enough to handle the unexpected.